Caught at the Port?

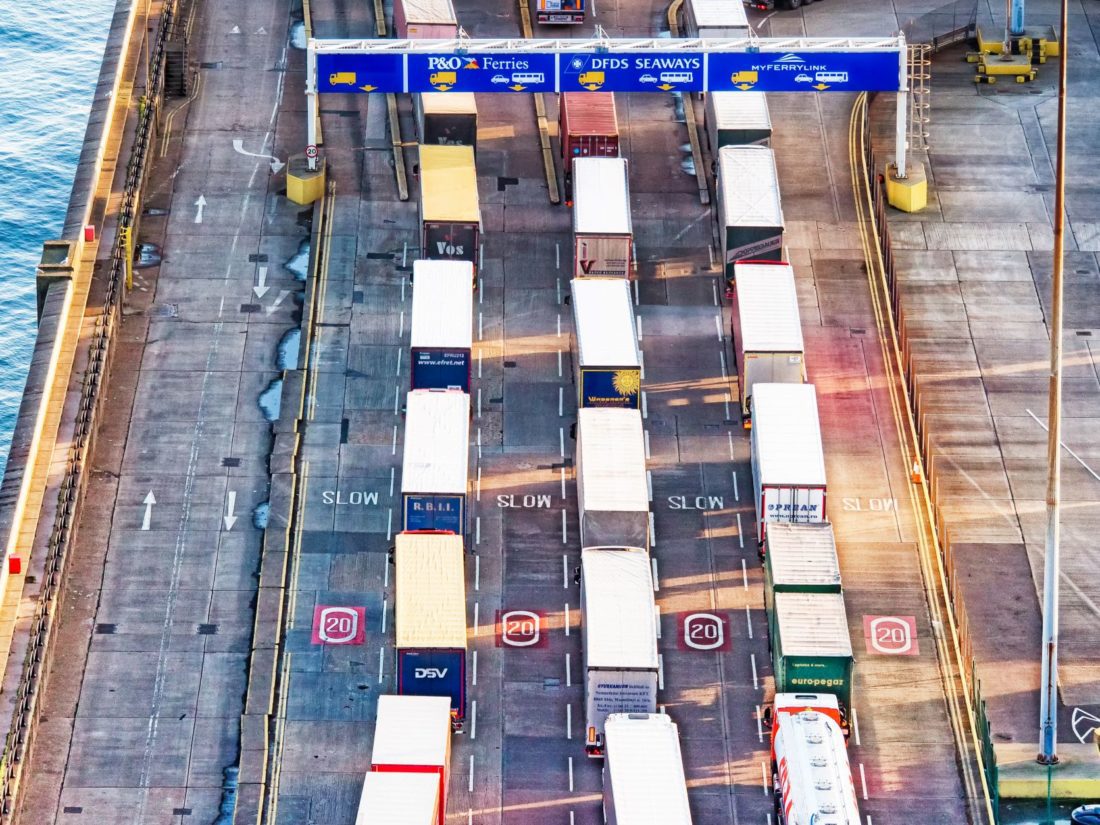

Reading Time: 3 minutesCaught at the port? Stuck in Customs? Awaiting further information from the receiver? Brexit and the pandemic have created a legacy of delays for many industries. There is a shortage of workers almost everywhere that you look, arguably, nowhere more so than the hospitality, manufacturing, and logistics sectors. Since Europe’s lockdowns were lifted, we have become familiar with restaurants opening for half the week; delivery vans emblazoned with their recruitment hotline numbers, as well as costly delays in the supply of both raw materials and finished goods. All exasperating for those of us who have become used to next day deliveries and a ‘open-all-hours’ culture.

At Fashionizer, every stage of our work has been challenged daily due to the dependence on complex international supply chains and their many moving parts. Like the hospitality sector, we operate in, and rely on, a global world where climate change, wars and pandemics affect us all – floods destroying cotton crops, escalating freight costs due to soaring oil prices caused by the conflict in Ukraine and, everywhere, the problem of recruiting and keeping employees becoming more evident. It looks like this labour shortage may not be temporary and could get much worse. It has been estimated that by 2030, there will be a shortage of 85 million workers around the globe. Alongside this, suppliers are increasingly affected by the decimation of their savings during the pandemic, holding less stocks, and requiring upfront payments.

Rules and regulations have changed in the UK post Brexit, adding complexity, time, and cost. The outcome of the 2016 vote to leave Europe allowed us to start preparing for this; even so, it has taken longer than expected to implement all the changes to our systems and processes. The level of paperwork for anything coming to or from the UK is legion and has led to us revising supply chain practices. Despite this we remain subject to varying customs processing times as well as couriers who take advantage of the situation in their prices.

Nevertheless, as we look to 2023, we are busier than ever and believe that the resourcefulness of all parties in their ability to adapt is key.

The pandemic, despite its devastations, has taught us to embrace change, leading to a number of positive adjustments, including revising our business models and introducing more remote working. We have also improved our sustainability practices, refining the circularity of business processes and the ability to recycle or reuse existing materials…. And our stationary consumption has gone down by 90%!

So, some advice as we head into a New Year?

- Firstly, plan well ahead, discuss your plans with us, things have changed and the lead time for some materials may be different to the last time you placed your order.

- Flexibility is key, prioritise and be prepared to change your original plan.

- Invest in materials early on to avoid the impact of inflation later down the line. We are delighted that many customers have taken our advice on this and have consequently already benefited, as materials have increased by 10%- 20% in 2022.

- Expect longer lead times than before the pandemic. Therefore, place your orders earlier than you may have previously done.

- Embrace sustainable solutions where possible; they can make sense to help you to positively engage with both your staff and guests.

More than ever it’s a time to share your problems and the solutions with your suppliers.

Happy New Year.

The Fashionizer Team

Comments: 0